British Manual On Stromberg Carburetor

Books.google.co.th - This totally revised, updated and enlarged book is THE complete guide to building a fast MG Midget or Austin-Healey Sprite for road or track. Daniel has been continuously developing his own 'Spridget' for years, and really does know what works and what doesn't when it comes to building a. The MG Midget & Austin-Healey Sprite High Performance Manual.

Among the greatest mysteries about Zenith Stromberg carburetors is exactly: “where does the dashpot oil go”? Usually, the reason is a rotten, leaky o-ring in the needle metering screw used to adjust the fuel-air mixture. This article will show you how to replace the o-ring. Updates:. Once you read this article, you might want to spend a few minutes reading the article’s comments at the bottom of the page.

There are some very interesting remarks there from folks who have contributed their knowledge. If you have any further insight, please make an entry so others might learn. If you are interested in getting the replacement O-ring necessary, please don’t forget to read the “Comments” at the end of this article. There is a source listed to where you can find the O-Ring. Required Tools: You will need to have several basic tools for this repair:.

A small flat-head screwdriver – to remove the retaining screw. A small Phillips screwdriver or better yet, a Pozidriv bit – to remove the four screws holding the diaphragm to the piston body. A Zenith Stromberg needle adjustment tool. If you don’t have one, you can get by with a long hex head tool. Some spray carburetor cleaner and a few rags or paper towels. If you are using a vise, don’t forget to get some soft jaw liners to keep from marring delicate surfaces. Here is a picture of the tools we will need.

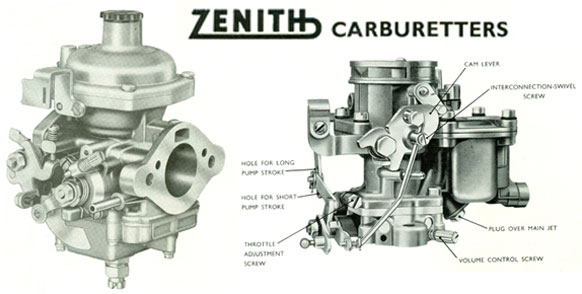

Zenith Stromberg carburetor cutaway diagram. The goal is to remove the needle adjusting screw pictured above.

The needle adjusting screw has a rubber o-ring that deteriorates through the years and this is what causes the dashpot oil to disappear. Before we begin taking things apart, please read this article completely and get familiar with all the parts and all the pictures. If you like, click on a picture for a larger image.

This is far from rocket science, just keep in mind the pieces are very small and are easily dropped. So take your time. Enough talk, let’s get started Step 1 – Remove the Retaining Screw Before attempting to remove the retaining screw, the needle adjusting screw must be backed out all the way out.

To do this, introduce the Zenith Stromberg needle adjusting tool (or suitable hex wrench) and make sure the hex head is firmly seated. Now turn counterclockwise a few times. Now lets work on the retaining screw.

Closeup of the metering needle still in the piston. Before we start taking things apart, please note the small notch on the side of the base of the metering needle. Note that it points in the direction of the orifice (basically it points in the direction of the retaining screw). The screw has a taper and it fits inside that notch. This keeps the metering needle screw from turning and allows it to move up and down. Even though the diagram above says the retaining screw is spring-loaded, I have yet to see one! All the carburetors I have taken apart have not had the spring.

However your carburetor might have the spring, so just be aware of its possible existence. Take the screw all the way out. Step 2 – Pull the Metering Needle Out With the retaining screw out of the picture, gently pull the needle out. If it won’t come out, you might have to use the needle adjusting tool and turn it counterclockwise some more. It is possible the threads of the seat are still in contact with the needle adjustment screw. Eventually the needle should come all the way out.

If the needle won’t come out it might be because there is some gummed dashpot oil residue. You might consider using some spray carburetor solvent and let it soak. Remember to use eye protection when you spray that stuff – it is not very eye friendly.

If after all this effort, the needle still refuses to come out, then there might be another thing to consider: the hex shoulders on the needle adjustment screw might be rounded out. This happens a lot from previous owners using the wrong tools or over tightening things. Remember, brass is SOFT! If this is the case, that might be the reason you can’t get your carburetor’s adjusted properly. At any rate, if you think the hex shoulders are rounded off there is another way to take the needle out and I have that procedure listed in “Step 6” below.

This is what it should look like once the needle is out. Metering needle, showing the little machined slot where the retaining screw fits into. This keeps the needle from turning when being adjusted. Step 3 – Remove the Needle Adjusting Screw The needle adjusting screw is where the o-ring is. This is what we need to fix. Removing this is a little tricky because what holds the needle adjusting screw in place is a little star washer that grips the walls of air guide valve rod. The best way to remove it is by placing a drift or wooden dowel in a vise.

Then place the piston on the dowel and very gently tap with a small hammer. Use a small block of wood between the piston and the hammer so you don’t strike metal against metal.

IMPORTANT: Make sure you have the piston in the correct direction. You want to put the side where the needle was against the drift or dowel. You want to tap the piston down, thus forcing the needle adjusting screw upwards so it exits on the top of the piston. Here is what things should look like once the metering needle screw has been “tapped” out. Brass housing for the metering needle Step 4 – Replacing the O-Ring As seen in the earlier pictures, the o-ring has flattened and does not fit tight. This one is in decent shape, however I have seen some that literally fall apart when the metering needle screw is taken out.

The replacement o-ring should be made of. Viton will hold up better to oil and fuel fumes.

Unfortunately, I do not know of a source for an o-ring this small. If you know of one please let me know and I can update this paragraph. This is also a good time to thoroughly clean the piston and make sure it is free of any carbon buildup. Finally a little Marvel Mystery Oil should be used inside the shaft so the new o-ring can slide easily – no point in messing up the o-ring during assembly after all this effort. Step 5 – Assembly Installing the metering needle screw with a new o-ring will take a little patience.

Place it at the top of the guide rod and gently push on it. You want to make sure it is level. Getting the metering needle re-inserted; note it is not a perfect 90 degree.

Instead it has a slight angle – read more about this in the comments section Now, get the hex adjusting tool and turn the metering needle screw as you push the needle in. Do this until it catches the threads on the needle. Of course, the needle will want to move around a little and this is where that detent will need to line up perfectly with the hole where the screw goes in. Put the screw back in and tighten it a little.

The following picture shows what the screw looks like fully seated. This is what the screw looks like all the way in without the metering needle. Now you see why the little notch has to line up in the exact place where the screw is.

You should now be able to turn the hex tool and the needle should not turn anymore. At this point you should see the needle start to walk back into the piston. This of course is the way you adjust the mixture in your carburetors. Step 6 – Alternate Needle Extraction Procedure If the needle refuses to come out gently, there is another way to get the needle out. No, it does not mean we get medieval on it!

I tried this on a spare carburetor and it worked. The needle can be pushed out from the bottom of the piston and this is done as follows. Mount the piston with the needle facing up like this: Now, carefully place a 4mm deep socket over the needle like this: Gently, very gently tap the socket with a hammer. You should see it start to move. Remember you will be tapping against the star washer, so this is going to have a little resistance. As this starts to move down, you will run out of travel on the socket. You will need to insert a slender, longer rod to gently tap the assembly out.

Eventually it should come out. I had to remove the metering needle on this carburetor to take all these pictures. It took a little patience but eventually the needle came out.

And, sure enough the hex shoulders had been rounded off. This is what the metering needle nut looked like. The little round disc is the Delrin washer. Basically I gently clamped the metering needle in the soft jaws on my vise. Once I had that clamped I tugged on the needle.

Since this is a spring-loaded affair, you can see the little black washer comes out with the needle. Diaphragm Alignment I have been asked how to align the rubber diaphragm. Well, there are a couple of alignment tabs on the diaphragm that must align with a matching grove. This is what the alignment tab and groove look like on the carburetor bowl. Alignment tab and groove, this time on the piston. You can see the piston has a groove (to the right of the two screw holes). The inside rim of the diaphragm has the matching tab.

Again, the diaphragm is upside down. If you line all these indents the diaphragm will be correctly seated and should seal properly.

You must align everything up before you securely screw the rubber diaphragm to the piston. About the Phillips Screws For some strange reason I have yet to figure out, the Brits made things complicated when it came to fasteners (after all, we have to thank them for Whitworth). I don’t know if you have ever noticed that a Phillips head screwdriver doesn’t fit right on the Phillips head screws on the carburetors. Well That is because those screws need a special bit. Pozidriv size #2 bit Do yourself a favor: go to your local hardware store, auto store, Sears, or whatever you have near and get a set of special bits for these screws. I picked up a handy three-pack which includes the #2 bit as well as the smaller one and larger one.

These will fit the Phillips screws perfectly and you won’t be rounding off those heads. They also work perfectly on the four screws that hold the carburetor lids in place. They can be really handy and no toolbox should be without them. Conclusion I hope all these pictures and my explanations are of some help to you. I don’t claim to be an expert in Zenith Stromberg carburetors (not even close!) – in fact I really dislike them.

This is the reason I like fuel injections so much. However these were tricks I learned when I owned a Spitfire. I hope you find this article of interest and it can help you solve your dashpot oil consumption problem. Comments are Very Welcome! As always, any suggestions, clarifications or questions are very welcome.

Like I said before, I am no Zenith Stromberg expert. However, this page has been read by many, many folks and if you have any other info that might come in handy for anyone with these relics of automotive engineering then please let me know. That is what the comments section below are for. ↓. Santiago Escalambre i thank you very much for sharing your knowledge in this field though you said you are not expert, i was impressed by the information you had shared.

I learned a lot after reading it. As you said ‘patience’ so i patiently read everything ’cause i have an MG MIDGET 1977 that had been seating in my garage for 30 yrs., and i finally made run but idle is very rough that i can not drive. Where can i buy this metering needle adjusting screw O-RING?

I checked Victoria BRITISH and MOSS parts stores but they dont have it. Thanks again. ↓. BC I had the Stromberg 175’s professionally rebuilt last year by a good carb guy here in Toronto.

The car starts well with the choke on and runs smoothly. However, after backing off the choke, it will not hold an idle and will stall. I was wondering if it was a full mixture issue but after reviewing the above article, I’d rather not have to mess with the adjustment if not necessary. It is still rather cool here these days; 6 Celsius, 42 F and the dash pot oil slows the piston movement down considerable; heavy upward movement and no pronounced ‘click’ when the pistons are dropped, and so I’m wondering if its simply a cold engine issue. Any thoughts would be appreciated. ↓.

John F Thanks for your post. I just stumbled on this post after I just finished removing and reinstalling the valve needle.

Had I seen this earlier, I would have replaced the o-ring while everything was apart. I guess this is a project for another day. I have a stock 79 mgb with a single 175 CD5T Zenith Stromberg with manual choke.

The automatic choke and some pollution parts were removed by previous owner, such as air pump, air pump cleaner and check valve. The gulp valve is in place but not plugged.

I can’t seem to lean out the carb. It runs so rich that my clothes become saturated with the smell of exhaust/fuel when the car is running even for even the shortest time. My plugs are sooty and it spits black soot out the tail pipe onto the garage floor. I don’t see any smoke from the tail pipe. I’ve tried using the special carb tool and turned the idle screws counter clockwise but nothing seems to help. Any suggestions on how to get rid of the stinky exhaust smell would be greatly appreciated!

Thank you in advance for your time. I worked on nearly the exact same car/carb setup (except for automatic choke) for a couple years trying to get it right. But the problem it had was too lean and I diagnosed vacuum leak early on. However, there were many leaks and of course I didn’t find the main one until I had fixed all the others, it turned out to be two access panels directly under the manifold on the driver’s side of the engine, bolts had come loose and gaskets were bad.

Having said that, I did run across a slightly rich problem while working on it, a buddy had replaced the fuel pump earlier and it had too much pressure. Those cars should only be running 4-6 PSI max (4 is better).

That ZS 175 sips fuel using vacuum only, and if the needle valve on the float isn’t adjusted just right, a strong aftermarket pump can flood the carb. And that is the only thing I can think of that could possibly cause it. If you haven’t rebuilt the carb already, I recommend you do so, and I recommend you also replace that o-ring. If it’s not holding oil, then it’s a source of vacuum leakage, and that carb is very sensitive to vacuum. ↓.

Scott Paradise It is possible to detach the needle valve from the adjustment screw by mistake by turning the adjustment screw counter clockwise too much, which obviously would keep you from being able to adjust the mixture. Pull the piston out of the carb and observe the needle while turning the adjustment screw. If the needle valve does not move, the screw has been turned counter clockwise too much, un-screwing it from the needle valve. Put some light force on the screw with the allen wrench and turn clockwise while lightly pushing the needle valve up into its bore. Once the screw and the needle valve are re-threaded you should be able to adjust the mixture.

Just be careful not to un-screw the adjustment screw too much! ↓. Very nice write up! The early ZS had the press to adjust jets, fixed needles. You can fit later pistons with adjustment to these early carbs. We use to just tap the jets up or down with a brass drift. I worked at a TR dealer c 1964 – the first ZS sighting on the TR4 – they were so bad the factory sent us SU on manifolds, told us to throw the ZS setups in the trash, complete.

I always found the O ring in the repair kits, but it is so small it often hides in odd corners of the bag or vanishes completely! Before I knew what it was for, I accumulated many, which of course I have since lost. I think the Delrin washer is only on some, certainly not all. It would be related to the needle holder assembly era. PoziDrive is a US patent, same owners as Phillips. What is weird is that the US makers did not adopt it as standard. It was invented to take more torque for power driven screws, and it does that very well.

↓. John House I struggled all winter to tune a 175CD ZS carb after rebuilding it (thanks to this blog for telling me how to replace the dashpot oil seal) in a ’79 MGB. ↓. Thanks for this article, I’ve owned and worked on my GT6 for over 25 years but had a problem that I was struggling to find a solution to, that was that the adjusting screw hex socket had rounded off. I was trying to figure out how on earth to change the screw if I couldn’t get it unscrewed to release the jet then I stumbled upon your article and the alternative method of removing the needle assembly was just what was needed. I’ve not found anywhere else where this method is explained so I’m very grateful, adjustment screw is now replaced and I’m able to tune my carbs again 🙂. ↓.

I just finished rebuilding the Stromberg on my 79 Spitfire. The article was a tremendious help to me. Two comments. The screw that holds the needle in does have a spring build into the point. Second point. To remove the complete needle assembly, I cut a piece of steel brake line about 5 inches long and placed the rolled end of the line over the needle and gently drove the the complete assembly out. Worked great so I will try to remember that trick next time.

Thanks for all of the great info. I had not worked on a side draft since my MGA purchased in 1960 so all the information was very usefull. I now have it in a note book.

↓. Post author David, Gracias por tu mensaje desde el Peru. En que parte vives?

Talvez en Lima? Esta es una gran surpresa saber que hay personas en Sud America que leen my blog. Me alegro mucho tambien que de algo te sirva esta guia para la reparacion de estos carburadores. Si no te importa la pregunta: que clase de ajustes tienes que hacer para que la mezcla de gasolina y aire sea la optima en la elevacion del Peru? Me imagino que ha necesidad de enriquecer la cantidad de gasolina, si? Pues bien – mil gracias por tu mensaje.

↓. Dave Rauch Regarding the spring loaded needle assembly, I have worked for many years on Volvo carbs both SU and Stromberg. The needles are actually loaded to rub on the jet on the engine side.

Earlier SU carbs needed the needles and jets to be centered but in 1971 the spring loaded needles were introduced to promote fuel flow from the float chamber. Obviously this caused needle and jet wear and they needed to be replaced when they became unadjustable. On inspecting the needle on my 76 Midget there is almost a notch from wear where it has rubbed on the jet. Interestingly- I’m having more of a problem making the mixture rich enough.

On the Volvo Strombergs there is a tool to press out the jet and press it back in, and the mixture can be adjusted with that tool. Volvos did not have the adjustable needle in the piston.

I’ve adjusted my carb on the MG all the way rich and it still is.60 CO at idle which is too lean and causes the HCs to go too high. I’m going to check the float level next- perhaps it was set too low.

By the way- the old saying “Righty richey” and “Lefty leaney” helps when adjusting your CO. My Midget is a Federal emissions car so it doesn’t have a catalyst. ↓. John House Excellent! Good info, Dave! I have noticed that the spring-loaded needle leans one way, when I reassemble it I will check to see if it leans engine-ward. I suspect you may be right for my case also, and it would make sense.

If the needle were to ride on the engine side of the jet, the fuel would basically split into two streams coming up out of the jet, causing a more thorough mixing, but if the needle rode centered in the jet the fuel would emerge in a single, perhaps slightly wide, stream as it’s pulled engine-ward. So perhaps the only purpose of the washer is to prevent splashing against the base of the needle housing at idle? Speaking of which, I wasn’t able to get any info on the washer from some Triumph experts, so I went ahead and ordered the needle assembly from Victoria-British thinking it would surely include the washer. I should have checked first, because it didn’t. Anyhow, I have the lean problem also. I had never adjusted the needle (didn’t even know about that until recently), but I had the idle mixture screws all the way in, and lifting the piston slightly at idle caused the motor to nearly die, so it was definitely running lean (and in fact inspecting the plugs verified that).

But I cannot detect any wear at all on the needle or jet. I am sure it’s the original one, this is a low mileage (30,000) 1979 MGB. But I don’t know where the needle was positioned when I disassembled it. So, hopefully, reassembly and a full tuning procedure will resolve the issue.

↓. Dave Rauch addendum to my reply- the Volvo needles were tilted toward the engine but today I found the Midget’s needle is tilted toward the air intake. Pulled the carb and checked the float level- it was in spec. Pulled the overrun valve and inspected the diaphragm and gasket – ok and the air mixture valve gasket was good as was the oring on that. Still running lean though.

/I’ve rebuilt the engine with rings and bearings etc but the previous rebuild was awful. Timing chain and marks way out of alignment, the tensioner was not even pressing on the chain and rubbed a hole in the cover! I wonder if someone has moved the jet up into the body? Are there any specs for that?

I’ve pinched off all the vacuum hoses one at a time to see if there was a vacuum bleed off. The needle in the Midget doesn’t have the delrin washer you’re talking about With the wear in this needle the mixture should be way rich. ↓. John House That Delrin washer may bemore important than I first realized. It sits at the base of the metering needle, which moved up and down in the jet orifice. Since the gas is sucked up out of the bowl through this jet, it might occasionaly splash up against the base of the air valve piston and so against the base of the needle, especially on deceleration or at idle when the piston drops. Without the washer, the gas can basically eter the base of the needle assembly, and work its way up from there to the o-ring sealing the oil chamber in the air valve.

Potential for long-term problems. That washer would prevent the gas from splashing against the base of the needle.

↓. John House Thanks! Wish I knew where to find one! The carb I’m trying to rebuild did not have one in it! I’ve contacted a Triumph auto club here in Ohio, they have members that store scads of extra carbs (most folks upgrade to Webers and don’t bother with these Zeniths). I thought of trying to make one, but my guess is that it is composed of a short thin sleeve with a flange. Having looked at the assembly up close, I can’t think of any other formation that would stay in place.

Difficult to duplicate. ↓. John House I can shed some light on the Delrin washer. It’s not the o-ring, as you guessed.

It’s actually a washer that sits at the top of the spring-loaded needle assembly, up against the hollow assembly body. If you look carefully at the bottom of the cutaway drawing at teh top of this page, the Delrin washer is labelled. With that knowledge, you can look at the needle pictures and actually see that washer. When that washer is missing, the spring-loaded needle moves loosely in the assembly body, so I assume its purpose is to keep the needle from moving excessively. I have the exact same question – how to we find this Delrin washer?

It must not be too important, as it is not mentioned anywhere else except that particular diagram, and it’s not in either of two rebuild kits I have purchased. ↓. Post author Thank you John, for the comment. There is a difference between the Delrin washer and the O-ring. It is clearly labeled in the diagram – just like you describe. The primary purpose of the O-ring is to keep the damper oil from leaking down.

I think we can both agree on that. As far as the Delrin washer, your assumption is probably accurate: its purpose is likely to help center the needle assembly in the brass lined opening at the bottom of the piston (see the picture following the diagram, above). Without it, the needle would not “center” properly.

At first glance, one would assume it is trivial and not needed. Without the needle “centered”, it would have a tendency to rub on the wall of the opening where fuel is metered. Basically this would result in an obstruction rather than a device used to allow proper fuel flow into the carb’s venturi. I always question the “norm”. Just because the Delrin washer is not part of a “kit” does not mean it is not needed or required.

Think about it, why would an engineer go to the trouble of having this little device included in a) the drawings and b) the final product? Components like this are there for a reason. Why would a manufacturer go to the trouble of making such a tiny part if it were not needed? When I messed with these carbs on my Spitfire, I bought several of the “kits” you mention. I still have them and you are correct, the Delrin washer is not included. However, just because it is not in the “kit” that does not mean it is trivial and it is not necessary.

British Manual On Stromberg Carburetor Overhaul

I would imagine it is too expensive/difficult to make the Delrin washer and thus it is not included. I wish I knew of a source for the Delrin washer – I don’t. However, I certainly would caution on simply removing this washer. ↓. Mats Sellner Thanks. This article helped me a lot. I would never dared to tap out the needle adjustment screw and retaining clip if I hadn’t found this guide.

You wrote that you hadn’t seen any spring together with the spring loaded retaining screw. That’s because the springs is inside the screw. The tip of the screw can move inside the hollow screw and the spring inside pushes the tip out against the small notch on the side of the base of the metering needle. I guess that’s why you can tighten the retaining screw and still adjust the needle when everything is mounted. ↓. Mats Sellner The new o-rings are in place.

It all went smooth, but I have the kind of needle adjustment screw with a raised blade instead of a hexagon recess, so there was a little challenge. When tapping the adjustment screw and retaining clip down with a drift, the drift hits the top of the raised blade, so the retining clip never goes the whole way down to fixate the screw. Therefore the base of the needle could move 0.8 mm (or whatever height the raised blade have) up and down with the adjustment screw. I guess this would have made it a little bit tricky to adjust the mixture in the end. The solution was to find some kind of tube among all my junk (I rarely throw anything away) with suitable dimensions. I was lucky to be able to cut of a short piece of brass tube from a discarded gas burner.

Outer diameter 8.5 mm and inner diameter wide enough to go clear of the raised blade, and 10-12 mm long. With the tube in front of the drift it was easy to tap down the retaining clip and fixate the screw. I have a picture if you get the idea to complement your excellent guide at a time. Sorry to hear about the lacking donations. I think it’s a great way to appreciate and support all the good non commercial initiatives out there.

The principle is simple. If you find something that has a value for you, well then pay something. I hope it gets more used in the future. Regards, and thanks Mats Sellner.

↓. Post author Mats, Thank you once again for your follow up and kind words.

This page just keeps getting better and people continue to visit here to get very good information on something that has really never been documented very well. Your idea of using the brass tube is brilliant. And, you are correct in stating that if this is not all driven correctly it would be difficult to gain proper adjustment on the needle.

Finally I really appreciate your kind words about donations. I established this blog not for profit, but knowing somebody thinks enough of this page to kindly donate sure is nice. Once again, thanks and happy motoring! ↓. George Butler Hi. Great information, you’re never too old to learn.

My needle retaining screw/plunger was solid locking the needle assembly so that it would not slide when I tried to adjust it. I had a similar problem with the float chamber needle valves on an old motor cycle carb and a local mechanic told me to drop them in a pan of boiling water for a few minutes. Just tried it again on the needle retaining screw and now works as it should. Don’t forget to dry and lubricate with light oil as they are not lubricated by petrol like the needle valves in a float chamber. Thanks again for a great article. ↓.

Post author If memory serves me correctly, the rubber diaphragm can only be mounted in a certain way: there is a small indexing mark that enables the proper orientation on the center of the diaphragm. Once that is properly located and the ring secured with the 4 phillips head screws you can look at the outside edge of the diaphragm. I believe that you will see there are also indexing tabs on the outside edge of the diaphragm that will fit only one way on the body of the carburetter. This will only go but one way and will properly align the whole affair. If this is not aligned correctly, I don’t think the plunger will work correctly.

I am writing this from memory. I no longer use these relics. I hope this helps. ↓. Post author Gerry Thank you for the question. Let me see if I can answer your question. I am not sure exactly, I follow what you refer to as the “delrin washer”.

Is a hard thermoplastic and I don’t think I mention it specifically by name in my article – correct me if I am wrong. Instead, I presume you are talking about the O-ring as described in the diagram on the second illustration of the article. If you look at the diagram, the O-ring is labeled on the left hand side of the cutaway diagram of the carburetter’s plunger. I suppose this is what you are talking about.

If so, I agree with you that the O-ring is NOT supplied in any of the “kits”. That is what makes this whole procedure such a “mystery”. All the kits I have seen, include everything but this very important O-ring. I suppose this O-ring is something that can be found at a hardware store however what you are going to find there is likely made of ordinary rubber. With today’s modern fuel formulations (especially if they are laced with ethanol) you will need to source an O-ring made of which will offer a longer life. I put this article together from some old junk parts I had lying in the garage and wrote it so others might benefit from it.

If anyone is reading this comment and know of a source and size of the O-ring please let me know so I can update the article and others might benefit from it. Finally, regarding the “slop” you describe: again, I am not following you. The O-ring is used to seal and seat the needle adjustment screw. This is what basically screws to the top of the metering needle assembly and keeps it from moving around. In addition, there is a slot on the metering needle that allows the spring loaded retaining screw to “lock” the whole affair together. If the O-ring is not on the needle adjusting screw I would suppose the entire assembly would not fit tight.

Finding a proper Viton O-ring is the trick here. I hope this helps answer your questions. If not, please give me some more details. ↓. John Salla My metering needle screw does not appear to be rounded off. My Allen (hexagonal) wrench fit snugly in the hole and I am easily turning it counterclockwise but the needle will not come out. I have just used my hands (no wrench) to try to pull out the needle.

I do not want to use step 6 to get the needle out since I will most likely destroy a properly working metering needle that I can adjust. What do you suggest I do? Should I forego taking the needle out? Your counsel and advice please. ↓. Post author John, Thank you for your question. I agree using a wrench might damage the needle assembly.

Question: did you take the small retaining screw out? If not, that might be the reason the needle assembly won’t budge. If the retaining screw has been removed then, it might be there is some residual fuel varnish holding the needle in place. You might want to immerse the piston in some solvent to see if the solvent might penetrate and dissolve any residual varnish.

Just be aware that a solvent might damage whatever is left of the “O-ring”. Another idea would be to turn the piston upside down propped on some small wooden blocks or on a jar. Then, spray some penetrating fluid or WD40 around the metering needle where it fits the piston.

The idea is to let gravity allow the penetrating fluid to enter and thus dissolve any residue preventing the needle assembly from coming out. Sorry I couldn’t be of more help.